Case Study

Kecen AC drive applied on rotary cutting machine without fixture

I. Overview

At present, multi-layer board manufacturers use the traditional centered round wood rotary cutting machine for processing in the veneer production process. This processing method has high accuracy and good quality. However, due to the presence of the wood fixture, when the diameter of the rotary log is about 200 mm, it cannot be processed on a rotary cutter with the fixture; and when the diameter of the log is small, the rigidity of the log is reduced and the quality of the rotary cut veneer is poor. If the remaining wood cores are discarded or processed into wood core boards, the raw materials will be greatly wasted, which will increase the production cost of veneer. Therefore, manufacturers generally use fixture-free round wood rotary cutting machines to re-spin the remaining wood heart, so that the raw materials are fully utilized.

2, The working principle of round wood fixture-free rotary cutting machine

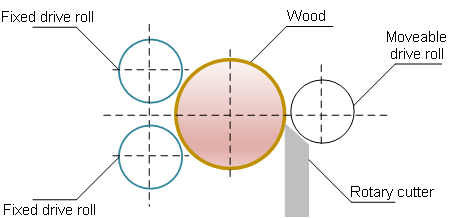

The working principle of the rotary cutter is shown in the figure below. The log rotates under the common driving of two fixed rotation rollers and one moveable rotation roller, and thus generates the cutting power. The center support of the movable driving roller and the rotary cutter are relatively fixed and move together. In this way, the rotary cutter will cut the sheet from the log, and the thickness of the veneer is determined by the gap between the movable roller and the rotary cutter and the speed of the rotary cutter.

The gap between the dynamic driving roller and the rotary cutting edge is relatively fixed. It is adjusted by the cutting edge gap adjusting device of the machine tool, which depends on the thickness of the rotary cutting sheet, and the moving speed of the rotary cutting blade controls the rotation speed of the driving motor through a control system. Therefore, the moving speed of the rotary cutter also indirectly determines the thickness of the veneer.

As can be seen from the figure below, because the rotation speed of the driving roller is constant, that is, the linear speed of the log is constant, and as the diameter of the log changes, the angular velocity of the log changes, that is, the time of log rotate one cycle is also changed, so the moving speed of the rotary cutter is a variable value and a non-linear relationship. The control of the traditional round wood center-less rotary cutting machine mainly changes the speed by electromagnetic governor, and the speed of the motor is changed by changing the input voltage of the controller manually adjusting the rotation or adjusting the cam curve. This rotary cutting control method produces a plate thickness deviation is up to 1mm. Therefore, it is especially important to design a system that can accurately control the speed of the rotary cutter to control the thickness of the rotary cutting plate.

The basic principle of system design is:

(1) Establish accurate mathematical models;

(2) Change the original speed control system to achieve accurate speed control.

3, Control System of Rotary Cutting Machine

This control system of the rotary cutter uses a KC500 high-performance vector inverter and a dedicated controller for the rotary cutter. KC500 series high-performance vector inverter uses TI's latest generation DSP chip, innovative use of three-core design, ultra-high-speed operation speed to ensure that the complex vector control is fully realized, torque response within 20ms, control accuracy ≤ 3%. The speed regulation ratio can reach 1: 200, the steady-state speed accuracy is ± 0.2℅, and 0.5HZ can output a rated torque of 180℅.

Apply the frequency inverter in rotary cutting machine has the following technical advantages:

(1) For complex rotary cutting objects, the starting torque is large to ensure that the motor has strong and balanced cutting force during low speed and heavy cutting, to ensure the smooth cutting and high-speed stop the knife and then restart the motor.

(2) Real-time dynamic high-speed calculation to ensure that the thickness of the rotary cutting is always maintained at the set value, so that the uniformity error of the veneer under normal rotary cutting is within ± 0.1mm. In some mechanical equipment, the lubricity is good, and the connection is accurate, the deviation can be controlled within ± 0.05mm.

(3) Super deceleration braking ability to ensure the instant stop of the knife motor.

(4) Strong adaptability. Aiming at the characteristics of therotary cutting machine, the operating voltage is designed in a wide range. In the case of voltage fluctuations, the output torque is kept constant, and the normal operation of the rotary cutting can work normally while the voltage is bigger than 60℅ of the rated voltage. This technology is especially effective for many bad power supply environments.

(5) The wide speed range is adjustable, the rotary speed is fast, the efficiency is high, and it can meet the requirements of high working efficiency system.

4, Conclusion

Kecen inverter control system simplifies the traditional rotary cutting machine mechanical structure, eliminates the deviation caused by traditional mechanical equipment, improves the accuracy of rotary cutting, and it also improves the machinery efficiency and the utilization of wood. After extensive application in various places, it is widely praised by customers for its stable control performance and good control accuracy.

2018-05-09

2018-05-09 Browse Times:

Browse Times:

Back to list

Back to list